Did you know that the most successful industries owe their efficiency to the obscure and often overlooked world of grinding machines? These unsung heroes shape our everyday products in ways you’d never expect. But there's more to grinding machines than meets the eye...

In today's rapidly evolving manufacturing landscape, understanding the intricacies of grinding machines is more crucial than ever. As demand for precision and speed in production grows, these machines are at the heart of innovation and efficiency.

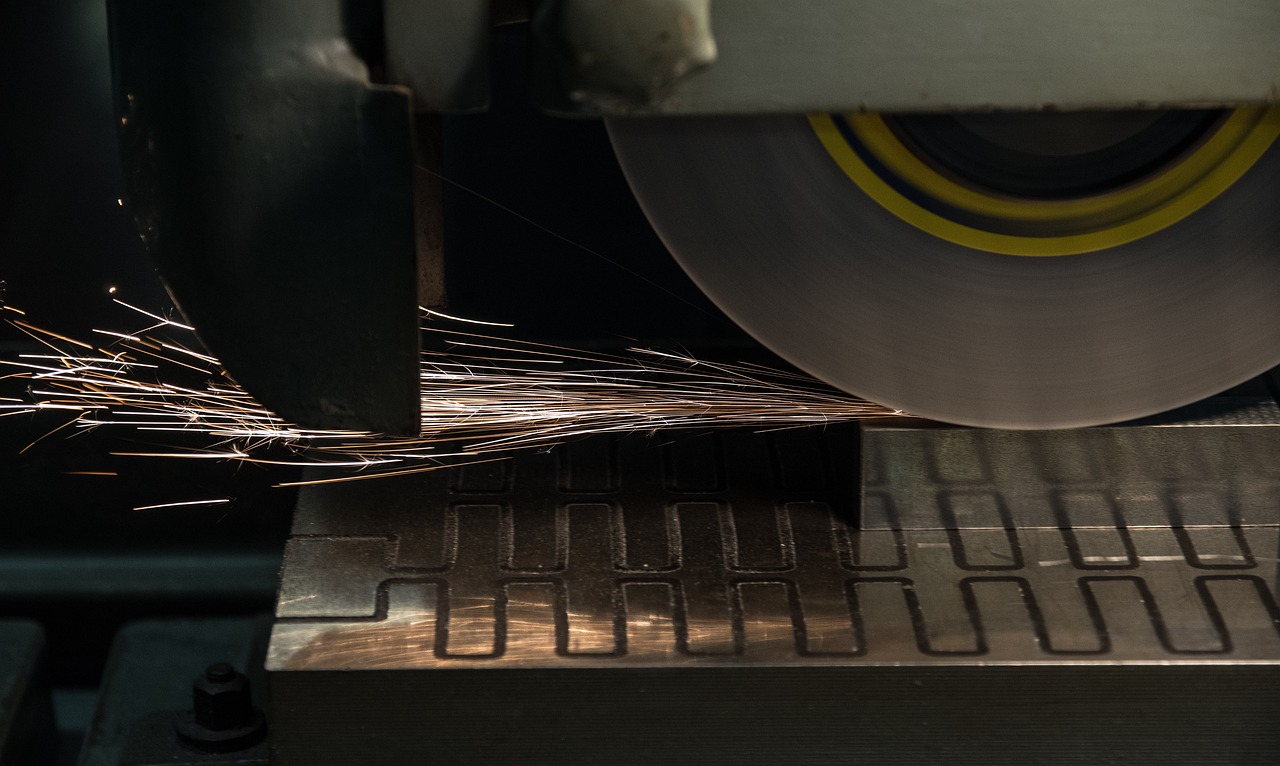

Grinding machines, often misunderstood, operate at such precision that they can be likened to the fine brushstrokes of a master painter. While most perceive them as mere metal-shredding giants, the truth is their capability to refine and perfect is unrivaled in the industry. But that’s not even the wildest part…

What if I told you that the evolution of grinding machines is directly tied to space exploration? As it turns out, these machines are critical for crafting components that withstand the harshest conditions known to humankind. Yet, their journey from humble origins to space-age technology is full of unexpected twists. But hold onto your seat because that’s just the beginning…

Engineers have spent decades harnessing the full potential of grinding machines. What happens next shocked even the experts, and it might just transform everything we thought we knew about manufacturing…

The journey of grinding machines began long before the rise of modern industry. Initially, they were rudimentary tools, crafted by blacksmiths to shape metal and stone. As society gravitated towards mass production, these machines were adapted and revolutionized. But this historical evolution is more than just industrial metamorphosis; it’s the story of perseverance and innovation. Yet, the journey doesn't stop there…

The Industrial Revolution was a turning point, where grinding machines took center stage. Suddenly, they weren't just tools but vital components in the production lines of factories worldwide. Their capability to create precision parts quickly and efficiently made them indispensable. However, the technological advancements that followed were nothing short of extraordinary…

By the mid-20th century, grinding machines had evolved to configure complex shapes and delicate compositions with laser-like precision. This advancement paved the way for technological breakthroughs in industries ranging from automotive to aerospace. And here's where it gets even more fascinating…

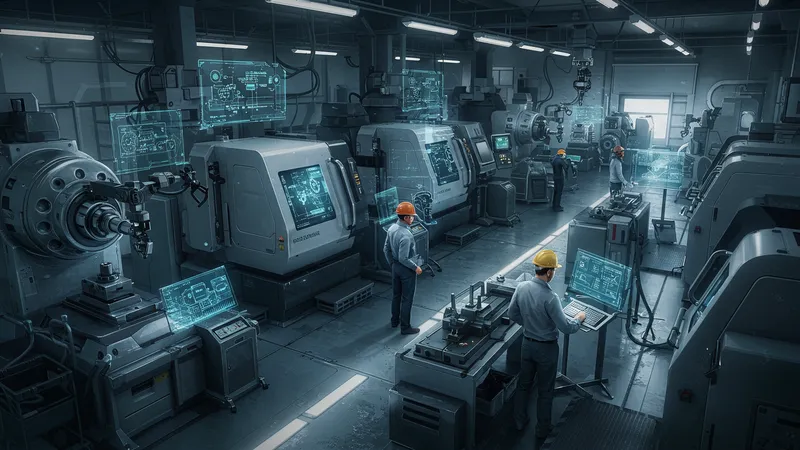

The next chapter of grinding machines’ history injects surprising elements of modern electronics and computer programming. These once manual machines have transformed into fully automated marvels of engineering. What you read next might change how you see this forever...

In today's mega-manufacturing plants, precision is paramount, and grinding machines are at the core of maintaining this exactness. But what happens when you peel back the layers of a state-of-the-art facility? Inside, you’ll find grinding machines working tirelessly to ensure that every product meets the highest standards of quality. But there's one more twist…

Interestingly, each grinding machine operates with a level of autonomy that can only be described as intelligent. Equipped with advanced software, they can adjust their functions in real-time, ensuring maximum efficiency and minimum waste. This smart technology not only reduces overhead costs but also maximizes productivity across the board. However, there’s a hidden component that takes this efficiency to unprecedented heights…

Maintaining these machines is not merely a process but a science. Technicians use predictive maintenance schedules, which rely on sensors and analytics, to foresee potential issues long before they manifest. This proactive approach ensures seamless operations and uninterrupted workflow. Yet, the brilliance of these machines still holds more surprises…

As you delve deeper into the workings of these plants, mysteries unfold that demonstrate just how vital grinding machines are. They pave the way for future innovations, and what you’ll discover next could redefine what you know about production technologies forever...

While grinding machines are renowned for their efficiency, there's a lesser-known side of the story — the hidden costs and the surprising benefits these machines provide. Despite their high initial investment, the automation, and reduction in manual labor saves significant sums in the long run. But here’s where the real shock lies…

The energy consumption of modern grinders is 30% less than their older counterparts, thanks to cutting-edge technology. This eco-friendly feature is a win for both businesses and the environment. Moreover, advanced insulation methods are also reducing noise pollution, making grinding machines not just financially sound but also environmentally responsible. But don’t take off yet, because there's an additional layer…

Understanding the comprehensive benefits that grinding machines bring to various industries extends far beyond simple cost savings. The ability to produce flawless components consistently raises product standards across several sectors. This not only translates to higher profit margins but also cements a company’s reputation for quality. However, the intricate advantages go even further…

With every rotation, grinding machines subtly shape the fabric of innovation and design. They empower industries to experiment, adapt, and evolve with precision that was previously thought unattainable. What you read next might just flip the narrative on what innovation truly represents...

The future holds uncharted territories for grinding machines, and the possibilities are seemingly limitless. Modern engineers and designers are pushing the boundaries of what these machines can achieve by integrating sensors, AI, and IoT technologies. But what’s even more fascinating is how these changes are unfolding right now…

Custom-design capabilities have leaped forward with advancements in software analytics and real-time data application. This has opened doors for bespoke projects that require high specificity, allowing for novel designs in everything from luxury vehicles to next-gen airplanes. Yet, there’s another surprising element to these innovations…

As industries lean further into automation, the role grinding machines play in the smart factory is becoming indispensable. The synergy among machines, computers, and human operators is creating a production environment that's adaptable and constantly improving. Still, the most staggering possibilities are yet to be unearthed…

The potential revolutionary capabilities of grinding machines in the realm of nanotechnology and material science beckon a future where the precise manipulation of atoms is within reach. What happens next might just redefine the essence of material creation…

In the quest for sustainability, grinding machines are emerging as unlikely heroes in the battle against waste. With increased emphasis on remanufacturing and recycling, these machines are pivotal in refurbishing existing parts. But you’ll be surprised to learn how they make an impactful difference…

Utilizing precision grinding, machines can restore worn parts to their original specifications with minimal material loss. This reduces the demand for new raw materials, keeping existing parts in circulation longer. But the story of sustainability doesn't end here…

Through innovative cooling and lubrication techniques, the energy efficiency of these machines is further optimized. The creative use of green technologies and sustainable practices signifies a step forward in the eco-conscious production approach embraced by companies worldwide. However, there’s a deeper aspect to consider…

Grinding machines are not only contributing to resource efficiency but are playing a crucial role in driving industries towards zero-waste goals. With each passing day, new techniques and strategies are incubated, promising a future where sustainability and efficiency go hand in hand. But what lies ahead might just alter the landscape of industrial practices forever...

In a world rapidly embracing the fourth industrial revolution, grinding machines have shown remarkable adaptability. With shifts towards Industry 4.0, these machines are on the cutting edge of technological advancements. What’s captivating is how they continue to evolve…

From manual calibration to digital integration, the transition has been nothing short of transformative. Today’s grinding machines can self-monitor, self-correct, and even predict necessary adjustments, ensuring optimal performance at all times. But there’s a more intriguing attribute to these adaptations…

Artificial intelligence is unlocking new capabilities within grinding machines, enabling them to learn from past operations and improve future outcomes. This results in continuous enhancement and a reduction in machine downtime, creating a smarter, more efficient production environment. Yet, the scope of these advancements stretches even further…

Such innovations are setting up a paradigm shift where grinding machines not only perform tasks but are also involved in decision-making processes. These smart systems are reshaping the backbone of manufacturing, promising a future of boundless possibilities. There's an exciting revelation that might transform the manufacturing sector at its core…

As technology continues to soar, the next chapter in grinding machines could redefine the very soul of manufacturing. Automation and artificial intelligence have paved the way for groundbreaking developments. But what’s next for this underestimated cornerstone of industry…

The rise of autonomous manufacturing is within sight, where grinding machines operate with minimal human intervention. This will radically reduce production times and elevate precision levels even further. Yet, there’s another dimension to consider…

Research is paving the way for machines that can perform intricate tasks previously reserved for human hands alone. The integration of advanced robotics promises capabilities previously thought impossible. But even this level of innovation is just scratching the surface…

As these machines embrace the future, the potential to interlink with economic, social, and environmental decisions appears more viable than ever. This synergistic approach offers hope for a transformative future, where efficiency, sustainability, and innovation coexist harmoniously. What you’ll learn next might reshape how you perceive the future of manufacturing…

While functionality is key, the economic implications of grinding machines on modern industry are profound. The initial investment might seem daunting, but the long-term savings and productivity boost they provide are significant. But here's where it gets even more intriguing…

By reducing reliance on manual labor, these machines lower production costs and decrease the margin for human error, improving overall quality and consistency. Invariably, these savings can be reinvested into innovation and growth. Yet, another economic angle is rarely discussed…

Automation leads to a reduction in waste, and as a result, businesses can greatly decrease their material costs. The sophisticated recycling mechanisms tied with grinding machines also contribute to a circular economy, emphasizing reuse rather than replace. What follows is an unexpected revelation…

Economically, grinding machines not only aid in reducing costs but also in heighting competitive edge. Companies harnessing these technologies see vast improvements in their ROI, and the future innovations promise even greater potential. There's a financial implication that might just revolutionize industrial economics, but first…

The ripple effect of grinding machines stretches far beyond production-line precision — they directly impact the quality of consumer products. But how profound is this influence…

The consistency and precision offered by these machines ensure that every product meets stringent quality standards, which is essential in today’s highly competitive markets. Less variability also equates to higher consumer satisfaction and loyalty. However, the intricacies of their impact extend further…

These machines are instrumental in refining a broad spectrum of products, from tiny electronic components to large automotive parts. This diversity in capability elevates the standard of production across various industries, leading to a new era of high-quality goods. But the story doesn’t stop there…

The application of modern grinding technology not only enhances existing products but also paves the way for novel innovations. With each precision-ground part, new potential emerges, setting a foundation for endless possibilities in product design and functionality. But the ultimate surprise in quality elevation awaits…

With the evolution of grinding machines closely intertwined with every aspect of modern manufacturing, it becomes increasingly evident that these machines are far more than just tools. They are the silent architects of industry innovation, efficiency, and precision. As industries continue to advance, grinding machines are poised to embrace their role in shaping the future of manufacturing, one precise grind at a time.

In this thrilling journey through the transformative world of grinding machines, we’ve only begun to scratch the surface of what these ingenious creations are capable of. The story doesn’t end here — it’s a continuous narrative of exploration and discovery, urging you to share your insights, bookmark for future revelations, and join the discourse on the hidden yet groundbreaking universe of grinding machines.