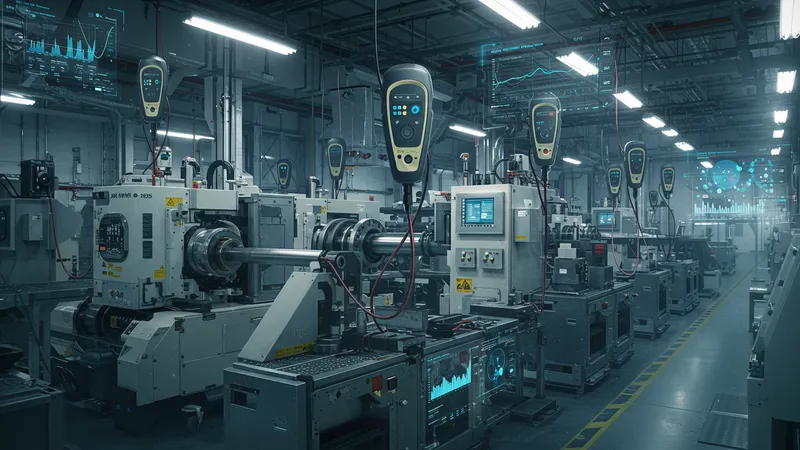

Imagine your industrial equipment whispering its status, predicting downtimes with precision, and optimizing performance seamlessly. Proximity probe monitoring solutions aren't just a futuristic dream—they are here, reshaping maintenance strategies.

In today's fast-paced industrial landscape, where even a minor disruption can result in staggering losses, investing in precision tools equipped with proximity probes is critical. But few realize just how game-changing these solutions can be.

Proximity probe technology goes beyond mere detection; it minimizes downtime, enhancing machinery life spans. These systems are transforming industries by offering superlative accuracy and signalling wear before a fault occurs. Imagine a conveyor shutdown saved by early alerts. But that's not even the wildest part...

Prominent businesses report a 30% increase in machine reliability, sparking a quiet revolution in machinery maintenance. Advanced analytics combined with wireless capability means conditions are monitored round the clock. But here’s an unexpected aspect: deployment is faster and less costly than traditional methods, making it accessible to smaller enterprises as well. But that’s not even the wildest part...

What's next shocked even the experts: the next evolution of proximity probe technology promises a leap in predictive precision. Curious about this groundbreaking advancement? You won’t believe how it's poised to redefine industries. Get ready to dive deeper into the unexpected, as we explore the intricacies of these solutions and the astonishing transformations they're bringing about.

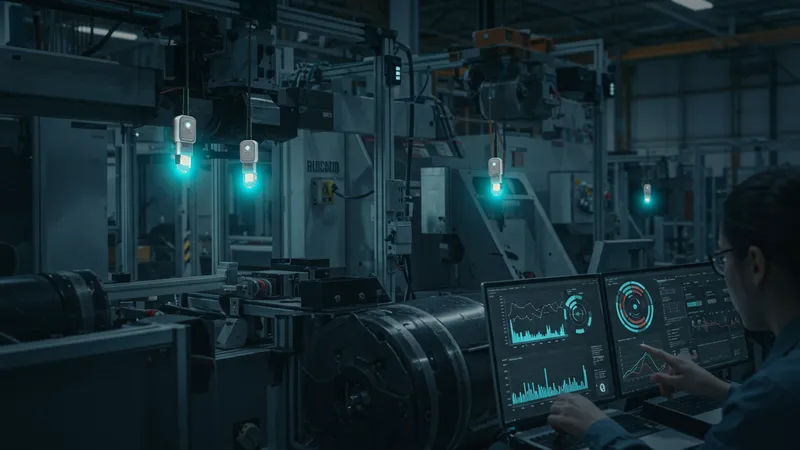

Every factory manager knows that machine breakdowns lead to unforeseen downtime, which translates into financial losses. Proximity probes stand at the forefront of the fight against unexpected failures by providing accurate monitoring of machinery movements. They detect changes you can’t see and warn you before things go awry.

These sensors have become the silent guardians of industrial health. With their ability to capture minute variations in positions or vibrations, proximity probes alert operators to potential failures. This allows for scheduled maintenance rather than reactionary fixes, preserving productivity and preventing costly halts in production lines.

Unlike traditional methods, proximity probes offer refined insights with real-time data. This empowers decision-makers with substantial information to optimize operational efficiency and prolong machine longevity. Being proactive rather than reactive changes the game entirely for industries on tight margins.

But there's one more twist: recent developments in AI-driven analytics integrated with these sensors are pushing the boundaries of what’s possible. What you read next might change how you see this forever—stay tuned as we delve into how AI enhancements are revolutionizing proximity probe technologies.

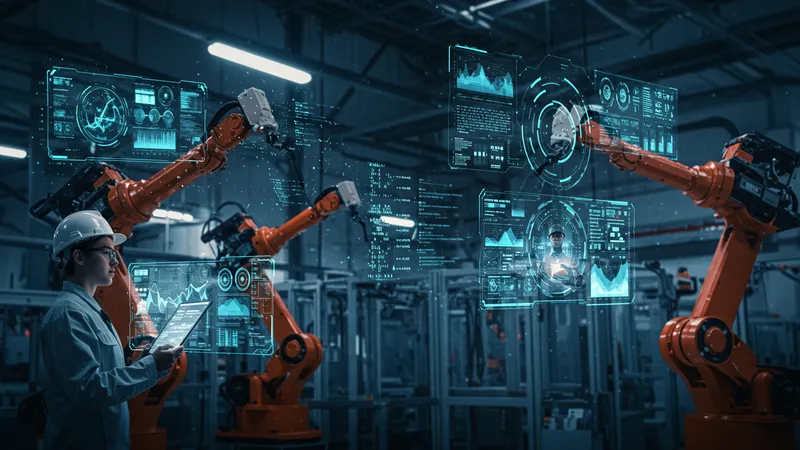

Artificial intelligence has permeated every sector, but when it comes to proximity probes, its impact is revolutionary. By analyzing the vast amount of data these sensors generate, AI can predict mechanical failures with uncanny accuracy.

This integration allows for not just timely alerts but also provides insights into the long-term behavior of machinery. AI algorithms detect patterns, helping maintenance teams to foresee potential failures weeks before they become apparent through standard checks.

Imagine being ahead of a costly breakdown due to predictive maintenance facilitated by an AI that learns and adapts. This brings businesses unprecedented control over their infrastructure, essentially turning maintenance from a liability into a strategic advantage.

What comes next could disrupt entire maintenance philosophies: combining AI with proximity probe data is not just enhancing reliability but is paving new paths in machine health predictions. Curious how this synergy could potentially save millions? Our next sections unveil these groundbreaking revelations.

Prolonging machinery life results in substantial cost savings—a fact often overlooked. With proximity probes accurately assessing equipment health, the lifespan of machines extends significantly, allowing businesses to reap higher returns from their investments.

This preventive approach to maintenance strengthens an organization’s bottom line. Industries that have integrated these technologies report notable financial benefits as equipment investments are protected and efficiency is improved.

Moreover, unexpected repair costs and replacement expenses are minimized, freeing up capital for investment in other growth areas. For many companies, this means being able to scale efficiently and focus on innovation rather than firefighting operational issues.

What you read next might change how you see this forever. Discover how leading firms utilize proximity probe monitoring for strategic financial foresight, uncovering the less evident but highly influential financial benefits.

Real-time data collection and analysis, powered by proximity probe monitoring, have revolutionized how organizations approach throughput optimization. Instead of relying on periodic inspection reports, managers now have constant visibility into machine performance.

This continuous flow of information means any deviations are noticed immediately, reducing the time between detection and corrective action. The upshot? Maximized throughput and minimized waste, both in time and resources.

Small adjustments, guided by data insights, can have far-reaching impacts on production efficiency. As these sensors pick up even the subtlest of changes, they help refine production processes in ways previously considered impossible.

But there's an intriguing twist: understanding exactly how these insights connect to bottom-line improvements. Want to see how real-time corrections translate into tangible success? Continue as we unveil more on how businesses are creatively leveraging these advanced metrics.

Human error is an unavoidable risk in industrial operations, but proximity probe monitoring offers a safety net. By automating the surveillance of machinery health, these systems effectively reduce the likelihood of oversight or human miscalculation.

Manual checks often miss minute but crucial details. Proximity probes, however, mitigate this by operating continuously, delivering precise measurements that operators can trust without uncertainty.

This means that corrective actions are influenced by reliable data rather than assumptions, ultimately leading to safer and more consistent outputs. The automation of these systems not only saves time but significantly increases operational safety.

Curious about the implications of lowering human error rates? The following pages uncover transformative insights on how these changes affect industry standards, setting new benchmarks for reliability.

Environmental sustainability is at the forefront of industrial evolution. Proximity probes contribute significantly by optimizing machinery use, reducing energy waste, and thus decreasing the carbon footprint.

With precise monitoring, industries can ensure machinery operates at peak efficiency, translating into lower energy consumption. This reduction is not only beneficial to the environment but also cuts energy costs, aligning economic goals with environmental responsibility.

Furthermore, with extended machine lifetimes supported by proximity probes, fewer resources are needed to manufacture replacements, promoting a circular economy.

But what if I told you that sustainability through these technologies comes hand in hand with increased profitability? Let these innovative solutions guide industries in marrying green practices with economic gain as we explore this happy confluence of interests.

Despite their promising benefits, technology adoption in industries can face hurdles due to perceived complexities and cost concerns. Proximity probe solutions, however, are breaking these barriers with rapid deployment and user-friendly interfaces.

Innovative solutions are designed with scalability in mind, making them appealing to both large enterprises and smaller industries. Many companies find the return on investment outweighs initial deployment costs, fueling wide-scale adoption of these systems.

The push towards automation and digitalization has accidental champions in proximity probes, proving not only to streamline operations but also serve as a gateway innovation for more complex digital adoptions.

And here's the twist: the democratization of such technology is swiftly transforming industries, small and large, with ripple effects that span economies. Stay tuned to uncover the strategies pioneering industries are using to seamlessly integrate these game-changers.

The rise of advanced monitoring solutions like proximity probes is reshaping workforce dynamics. Operators now require skills to interpret data and maintain advanced systems, paving the way for a new era of industrial training.

This shift not only enhances role significance but also empowers individuals by providing them with insights formerly reserved for specialized technicians. Companies investing in training programs see improved staff satisfaction and efficiency.

With machines handling routine checks, human efforts can be redirected to problem-solving and innovation, adding value in ways that were previously unexplored. It's a paradigm shift that aligns with the future of work, emphasizing upskilling.

What happens next? Discover how continuous learning programs are not only supporting technology integration but also reshaping career trajectories in ways you wouldn't anticipate.

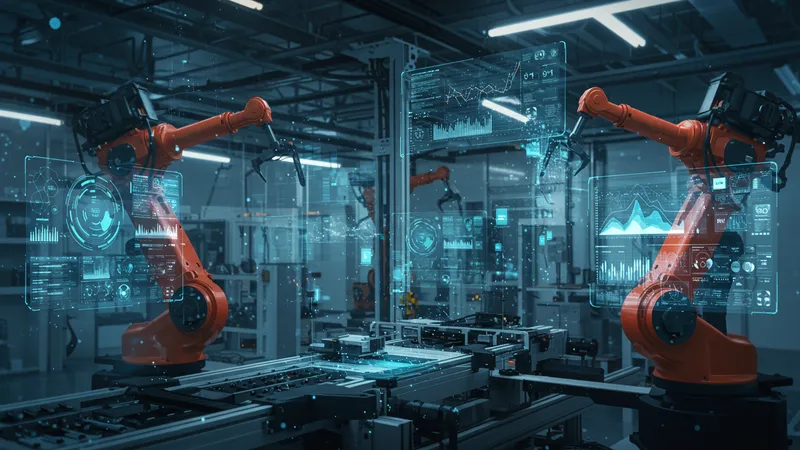

As proximity probes evolve, their role expands beyond current boundaries, hinting at future potentials in interconnected systems and smart factories. The vision? A completely autonomous industrial environment guided by principle-driven analytics.

Such advancements foreshadow a future where systems self-regulate based on real-time conditions, further reducing the need for human intervention and error. This envisionment is hinting at unprecedented operational efficacy and safety.

From predictive maintenance to integrating with AI and IoT ecosystems, proximity probes are evolving into colossal contributors within the Industrial Internet of Things (IIoT). The possibilities they introduce are game-changing, to say the least.

And here's a futuristic tease: as we edge closer to fully intelligent industrial systems, these probes play a quintessential part. What you read next will delve into the visionary insights that could redefine how industries operate in the coming decades.

Businesses are learning to rethink strategies by leveraging real-time data and analytics offered by proximity technology. It’s more than operational; it’s strategic innovation born from precise data-driven insights.

Strategists now employ these perspectives to craft resilient policies and practices that anticipate change rather than react, turning unpredictability into an opportunity. Now, traditional strategies are being transfigured into dynamic, adaptable approaches.

This evolution demands a new holistic perspective, unifying disparate systems into a cohesive, insightful network that propels businesses forward with articulate data interpretations.

How does this impact competitive landscapes? As we reveal how forward-thinking organizations harness these tools to maintain a competitive edge, you’d be surprised at the transformational power within these technological trends.

Despite the glowing prospects, some myths around proximity probe technologies remain pervasive, often dissuading potential adopters. These include misconceptions about cost, complexity, and benefits versus traditional methods.

In reality, the deployment is often quicker and more cost-effective than anticipated, challenging long-standing skepticism. Users frequently label the technology not just as superior but also as simpler and more integrative.

Nonetheless, demystifying these beliefs requires clear communication and education. The technology proves its worth by exponentially benefiting those who delve deeper into its capabilities. This illumination not only welcomes more users but increases trust in technological progress.

As we further dismantle these myths, prepare to shift your thinking and embrace proximity probe solutions as the proven path forward. Unveil practical examples that demonstrate their undisputable efficacy in real-world applications.

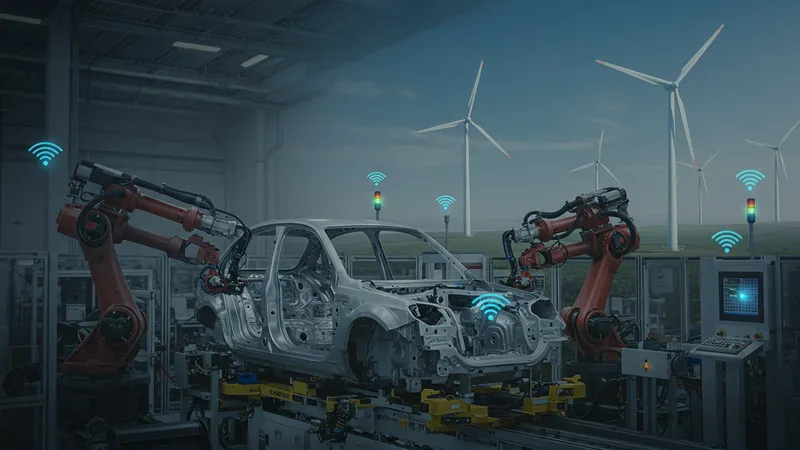

The versatility of proximity probe solutions stretches into nearly every industrial sector imaginable, offering valuable applications beyond mere machinery maintenance, including robotics and aerospace.

Consider automotive assembly lines, where these sensors ensure precision at every stage, reducing errors and improving throughput. Or, look at wind farms, where they monitor turbine efficiency and predict maintenance notwithstanding environmental conditions.

This level of adaptability has far-reaching effects, transforming how equipment is managed and maintained. By adopting these solutions, industries can harness the true potential of their machines, ensuring longevity and optimal performance.

Ready to uncover more jaw-dropping examples? Continue to explore the unexpected versatility and real-world successes of these innovations as we dive into more detailed use cases.

Success leaves clues, and in the realm of proximity probes, there are spectacular stories just waiting to be uncovered. From small startups to industry giants, businesses worldwide are reaping the rewards of these monitoring solutions.

Take, for instance, a mid-sized manufacturing firm that credits proximity probes for a remarkable 40% reduction in downtime. Their transition illustrates how strategic implementation can result in spectacular competitive advantages.

On a larger scale, multinational corporations report astounding cost savings due to predictive maintenance enabled by proximity technology, reflecting significant bottom-line improvements year over year.

Inspired by these stories? Learn how these triumphant examples serve as benchmarks for others aiming to maximize their potential. It’s more than a technological shift; it’s an industry-altering transformation.

Where hardware meets insightful analytics, proximity probes represent the next stride in industrial evolution. The blending of IT and OT platforms powered by these innovations ensures seamless operations across various infrastructures.

Companies adopting such integrative approaches are quick to acknowledge the uptick in operational coherence, optimizing resource allocation while minimizing friction points between systems.

The intersection of these tools with strategic insights proves invaluable. As industries grapple with growing complexities, merging technological governance with day-to-day operations stands paramount.

Curious to see how these integrations unfold? Ahead, you’ll explore the tangible results when innovative tooling, insightful analytics, and strategic execution collide, culminating in revealing aspects crucial to modern industrial landscapes.

As the curtains draw on proximity probes, the horizon reveals even more exciting prospects. Their adoption heralds new, emergent technologies like autonomous systems and self-diagnostic machines, set to push boundaries further.

Forward-looking firms are already experimenting with next-gen sensors that could not only signal maintenance needs but also remedy them autonomously, telegraphing a shift towards self-sustaining, intelligent industrial ecosystems.

The symbiosis between real-time insights and automation promises to revolutionize operational landscapes, driving us towards an era of efficiency unparalleled in history. The trajectory is set, and the future promises unexpected yet exciting technological confluences.

The climax? The industrial narrative is at a threshold where the merging of intelligence and autonomy transforms possibilities into realities. Share, bookmark, or act now to stay ahead—don’t let this technological wave pass you by.