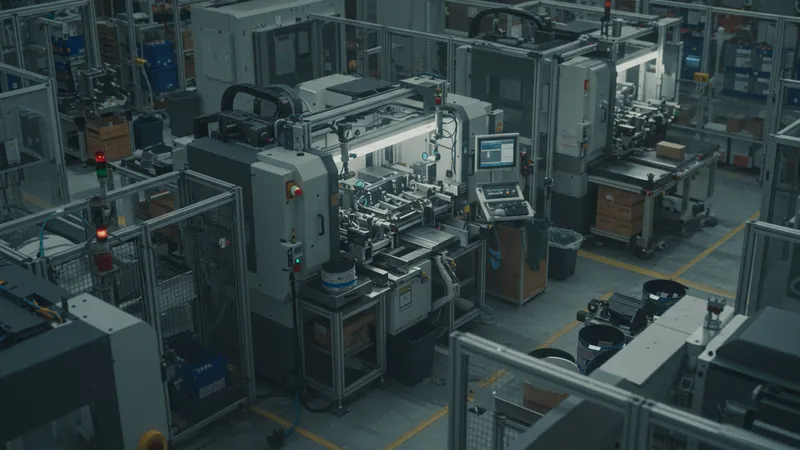

Did you know that a remarkable 70% of products we use daily are manufactured using industrial machines? This monumental figure underscores the undeniable influence of these machines on everyday life.

As global supply chains face unprecedented challenges, the role of industrial machines in keeping industries alive is more crucial than ever. Businesses must adapt or risk being left behind.

Industrial machines are not just making products; they’re revolutionizing manufacturing with artificial intelligence and automation. The results? Unprecedented precision and efficiency replace human limitations in quality control and production speed. But that’s not even the wildest part…

Even industries that once resisted technological integration are now embracing cutting-edge machinery. These innovations are creating new marketplaces and opportunities while redefining the global economic landscape. But what happens when machines surpass human capabilities in decision making? But that’s not even the wildest part…

The implications of industrial machines go far beyond the factory floor—they reach into every fabric of modern society. What happens next shocked even the experts…

While the advancements in machinery have brought immense benefits to manufacturing, there's a lurking downside that rarely gets mentioned: the hidden costs. Operational expenses can skyrocket with the maintenance of these state-of-the-art devices, particularly when parts are hard to source or need specialized skills. But there’s one more twist…

Tackling these hidden costs requires navigating complex logistical hurdles. Often, machine downtime isn't just costly in monetary terms—it can stall production lines and disrupt entire supply chains. Insider tip: streamline procurement processes to mitigate these risks, but that's just scratching the surface. What you read next might change how you see this forever.

Environmental regulations demand new machinery comply with eco-friendly standards, often requiring expensive modifications or upgrades. This compliance is crucial, but it can erode the anticipated savings from increased efficiency. But the true challenge goes beyond initial costs...

Many manufacturers find themselves trapped in debt cycles from financing heavy machinery, which can ultimately cripple innovations and adaptability. To survive, businesses must strategically plan both short-term financial risks and long-term growth. How this strategy unfolds is rarely straightforward... Keep reading to discover the surprising truths ahead.

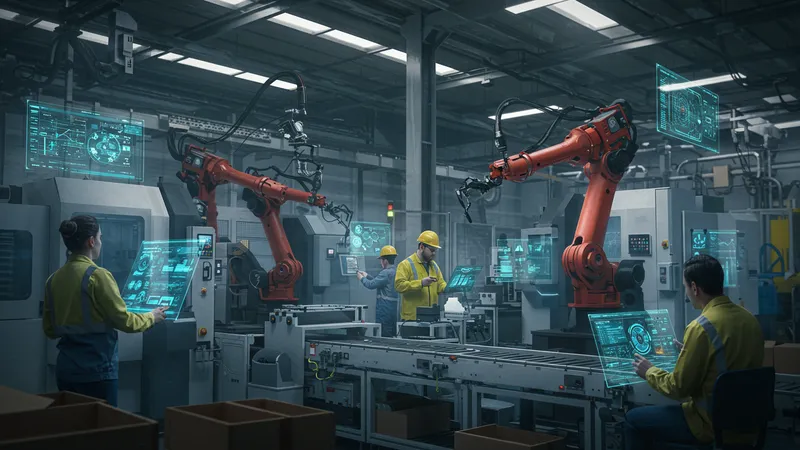

Automation isn’t just an upgrade; it’s a revolution. Machines now handle tasks previously thought impossible without human intervention. However, automation brings with it a seismic shift in the labor market. What does this mean for factory workers?

For many employees, automation introduces fear and uncertainty. Job descriptions evolve as monotonous tasks are replaced by robots, reshaping the workforce's role to focus more on machine oversight and less on manual labor. Yet, with proper reskilling, the potential for workforce augmentation is immense.

A study found that re-training programs drastically improve job security for employees impacted by automation, yet only a fraction of companies invest sufficiently in such initiatives. The remaining companies risk falling behind, but the untold stories of success with automation might surprise you.

Despite the challenges, automation can lead to remarkable efficiency gains, enabling companies to scale operations to unprecedented levels. Still, many wonder: will the human touch become obsolete? What lies at the heart of this digital revolution shakes the very foundation of traditional manufacturing...

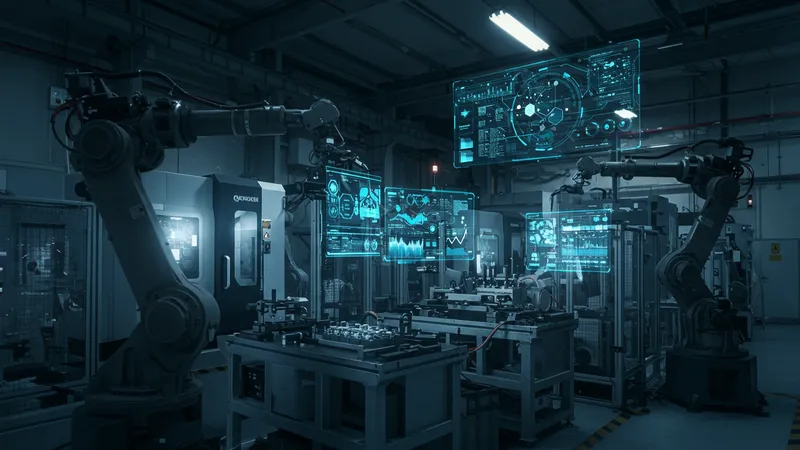

As AI technologies weave into industrial machines, the potential for intuitive manufacturing has never been clearer. AI isn't just learning to think; it's learning to innovate. Imagine a system that autonomously improves production methods—an exciting though unnerving prospect for many.

AI can detect flaws that even seasoned inspectors might miss, potentially saving millions in waste annually. Yet, some fear over-reliance may bring vulnerabilities or oversights that humans are better equipped to catch. Does AI truly have manufacturing's future in its hands, or is there more at stake?

Enterprises leveraging AI report a significant reduction in human error and an uptick in overall efficiency, yet the nuances of implementing such technology remain complex. With each success story, there comes a cautionary tale of systems going awry, which makes navigating this transition critical. But if you think this is impressive now, wait until you see what lies further ahead.

Despite the uncertainties, aligning AI with manufacturing goals is rapidly becoming non-negotiable. The allure of what AI brings to the table makes it a formidable force. But is the industry ready for what comes next? The answer might not be what you're expecting...

Robots are no longer restricted to assembly lines; they're taking roles as collaborators in the workspace. Collaborative robots, or cobots, work alongside human coworkers, lifting the industry's potential to new heights. But how does this dynamic alter human-machine interaction?

These cobots are programmed to navigate complex tasks, offering adaptable support rather than mere replacement. However, they necessitate new safety protocols and training paradigms, altering the fabric of workplace safety.

The adaptation to robot colleagues hinges on enhancing human skills for synergy. Companies that invest in training employees to work with cobots have reported significant boosts in productivity, as well as job satisfaction. But can this harmony be sustained long-term?

Such coexistence presents novel opportunities and challenges, pushing the boundaries of the collaborative workspace. Nevertheless, the reality looms: Are we ready for a future where robots might not just support but outpace human ability? The possibilities are as vast as they are daunting...

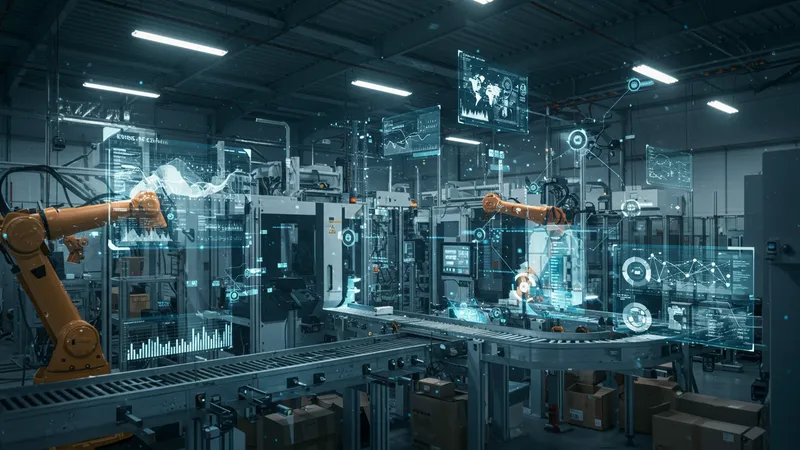

As manufacturing machines take center stage, supply chains need to adapt dynamically. A machine-led supply chain brings benefits but also complexity, requiring infrastructure enhancements that many are not prepared for. What role do these machines truly play?

Machine-driven operations foster unprecedented responsiveness, allowing manufacturers to adapt quickly to market demands. However, this agility necessitates real-time data processing and robust connectivity, often lacking in current systems.

The integration of IoT in manufacturing means supply chains operate on accurate, up-to-the-minute information, transforming the logistics landscape. But the heavier reliance on interconnected devices poses cybersecurity risks rarely addressed in traditional systems. Yet, the opportunity here is vast for those who can navigate the technological minefield.

What emerges is efficiency at net-zero costs, but achieving this equilibrium demands a complex orchestration of pursuits for innovation. What's next promises to be both exciting and challenging as manufacturing giants seek to fortify their supply networks...

Industrial machines were supposed to usher in a green revolution, but have they truly delivered on this promise? The debate rages on as improvements in production efficiency clash with hidden environmental costs. Would you reconsider the environmental impact of your operations?

Greater efficiency often paradoxically escalates resource consumption and energy use, undermining sustainability goals. New machinery with greener paradigms sometimes require more resource-heavy models, paradoxical to initial intentions.

On the flip side, many machines promise reductions in waste and emissions, yet translating technological potential into measurable environmental impact remains a contentious issue. Scrambling for sustainability certifications adds another layer of complexity and cost.

In contemplating eco-friendliness, industries are met with the paradox of modern innovation: Can one truly achieve efficient production, reduced footprint, and client satisfaction all at once? The conclusion of this puzzle might just flip your current assumptions...

The world economy is witnessing a paradigm shift with industrial machines at the forefront. Emerging markets gain unprecedented accessibility to advanced tools, leveling the playing field, but at what economic cost?

Countries previously reliant on manual labor now embrace automation, boosting productivity and competitiveness. However, rapid technological adoption can foster economic disparity, leaving economies unprepared for such transitions struggling.

The opportunity for increased prosperity exists, but only if managed carefully. As machines replace jobs here but create them elsewhere, governments grapple with finding a balance in policy and infrastructure investment.

On a global stage, machines as economic accelerators paint a promising future, yet the balance between technology adoption and social stability remains ever delicate. Are we ready for the next chapter in economic evolution?

Not everyone is on board with the industrial automation wave. Companies and individuals face various hurdles and perceptions in adopting advanced machinery. Is this resistance a misunderstanding or a growing concern that goes beyond financial implications?

Fear of the unknown and attachment to traditional methodologies often hinder progress. Businesses that fail to modernize risk obsolescence, yet understanding the hesitation is crucial for successful transitions. How can businesses address these reservations effectively?

For some, the costs associated with new technology are prohibitive, and the return on investment isn't immediately clear. Others worry about workforce displacement, suggesting that the human factor might be sacrificed in pursuit of efficiency.

But as industries evolve, adaptation becomes a necessity rather than a choice. Overcoming resistance by investing in adequate training and communication strategies could hold the key to harmonizing technology with traditional practices. Yet the question remains: How can this delicate balance be struck?

As machines make more decisions, ethical considerations become an ever-present topic. There’s a growing debate on the morality of entrusting machines with decisions that impact lives directly. Where does one draw the line at human oversight?

The potential for bias and error in algorithmic decision-making is a concern, with the prospect of flawed automated conclusions carrying significant societal implications. Highlighting the need for rigorous evaluation of these systems before deployment is paramount.

However, when designed transparently and monitored properly, machine decision-making can enhance fairness and efficiency. The ethics of allowing machines to make qualitative judgments continues to divide opinion, posing questions as yet unanswered.

This moral ambiguity leaves room for more discourse on how to ethically integrate AI into decision-making processes. Are regulatory efforts keeping up with the pace of technological advances, or is this a realm governed by the Wild West of innovation?

Contrary to fears that machines might limit innovation, they are increasingly recognized as enablers of creativity within industries. By handling the mundane, they liberate human capital to focus on innovation and strategy. But what happens when machines cross the line from support to creator?

Machines equipped with AI are starting to contribute creatively, developing solutions that would take humans significantly longer to conceptualize. The challenge moving forward is to harness this machine-driven innovation without undermining human ingenuity.

Within research-focused sectors, machines are already outperforming human counterparts in experimental design and testing timelines. The competitive edge could be life-saving in industries such as pharmaceuticals and aerospace.

What remains to be seen is the long-term impact on the creative process. Will human intuition continue to guide machine learning, or will innovation itself become an automated protocol? The conundrum settles on the horizon of a future rapidly closing in, ready to redefine what we consider possible.

As the use of industrial machines grows, so does their ability to enhance human capabilities. Machines don't just augment physical abilities—they amplify human intellect by processing data and outputs in ways unimaginable before. How far can this symbiotic relationship go?

From exoskeletons aiding in physically demanding jobs to AI systems revolutionizing data interpretation, technology is not just a tool but an extension of human potential. Yet, this reliance on machines introduces a new dependency we must carefully manage.

The coupling of human intuition with machine precision is creating new paradigms of capability expansion, offering unique opportunities for progress. However, much of this potential remains untapped due to apprehensions and regulatory bottlenecks.

Nevertheless, this augmented existence holds vast possibilities, hinting at a future where limits of human capability are only bound by our imagination. Will this augmentation define the next phase of evolution in business and beyond? Prepare for unexpected revelations as we delve deeper...

The future of industrial innovation strongly depends on effective policy frameworks that foster growth and simultaneously address the challenges of automation and AI integration. These frameworks can make or break a country's manufacturing prospects. Are current policies paving the path for advancement?

Policymakers face a tough balancing act: fostering innovation while ensuring that technological advances safeguard employment and address workforce transition needs. Striking this balance becomes critical as machine influence grows broader and deeper.

Countries leading in supportive industrial policies boast economic resilience, yet even these nations face the challenge of keeping policies up to pace with rapid advancements. In contrast, those lagging face further isolation from the innovation arena.

The path forward involves iterative policy crafting, informed by a technology-focused dialogue, which considers both potential benefits and ramifications. How close are we to achieving adaptive policies that can sustain this fast-paced technological evolution?

Industrial machines are poised to become even more integral to society, reshaping industries, economies, and, eventually, everyday life. Their prevalence raises the question of how society will look in the near future. Are we equipped to handle the changes these machines will bring?

As they take over functions previously managed by humans, machines will redefine the scope of what could be considered a product of human endeavor, creating a paradigm where man and machine are co-creators.

The vision of future society blends improved quality of life with complex dichotomies. Efficiency continues to rise, but questions about fairness, access, and control amplify discussions about our industrial future.

Ultimately, the coming transformation challenges us to question what we value as a society and what we're willing to sacrifice in the name of progress. Will the transformation secure a prosperous future or open an era of unprecedented challenges? The narrative continues to unfold...

Industrial machines, the undisputed backbone of modern manufacturing, are set to continue reshaping our world in ways we’re only beginning to comprehend. As we stand on the brink of this next industrial revolution, are we truly prepared to harness the power and potential these machines bring?

What’s clear is the importance of adapting quickly, not just technologically but socially and economically, to the role of these machines. As they become ever more integral to our global framework, sharing insights, and sparking discussions about their impact isn’t just beneficial—it’s essential. Bookmark this story, share it with others, and join the conversation. The future is advancing, and now is your moment to be a part of shaping that narrative.